Process control using AI on a digital twin of an extraction column in VR

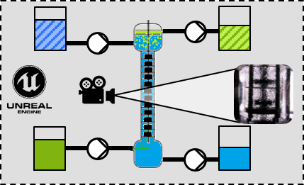

The digital laboratory consists of two flexibly combinable parts. In the first part, an extraction column is operated in virtual reality (VR) as a digital twin. The laboratory setup, experimental conduction and possible measurement methods are displayed. In the virtual environment, the flow diagram and the real plant setup are juxtaposed. In addition, the control concept of the plant and the influence of the individual column parts during its operation can be investigated by means of controllers on the feed pumps and level sensors on the column. Via a virtual camera in the virtual environment, previously recorded real test data is "recorded" and output for evaluation. Users set up an experimental plan with the aim of recording measurement points of different plant operating points.

The second part of the digital laboratory deals with the evaluation of the experimental data in order to find the optimal operating point of the plant. Here, droplet sizes in the captured images are to be classified by applying AI-based image analysis. The code required for this will be developed in the open-source software Jupyter Notebook.

Contact

TU Dortmund

AG Apparate Design

Fakultät Bio- und Chemieingenieurwesen

name: Alexander Behr

email: Alexander.Behr@tu-dortmund.de

name: Laura Neuendorf

email: Laura.Neuendorf@tu-dortmund.de

name: Piriyanth Sakthithasan

email: Piriyanth.Sakthithasan@tu-dortmund.de