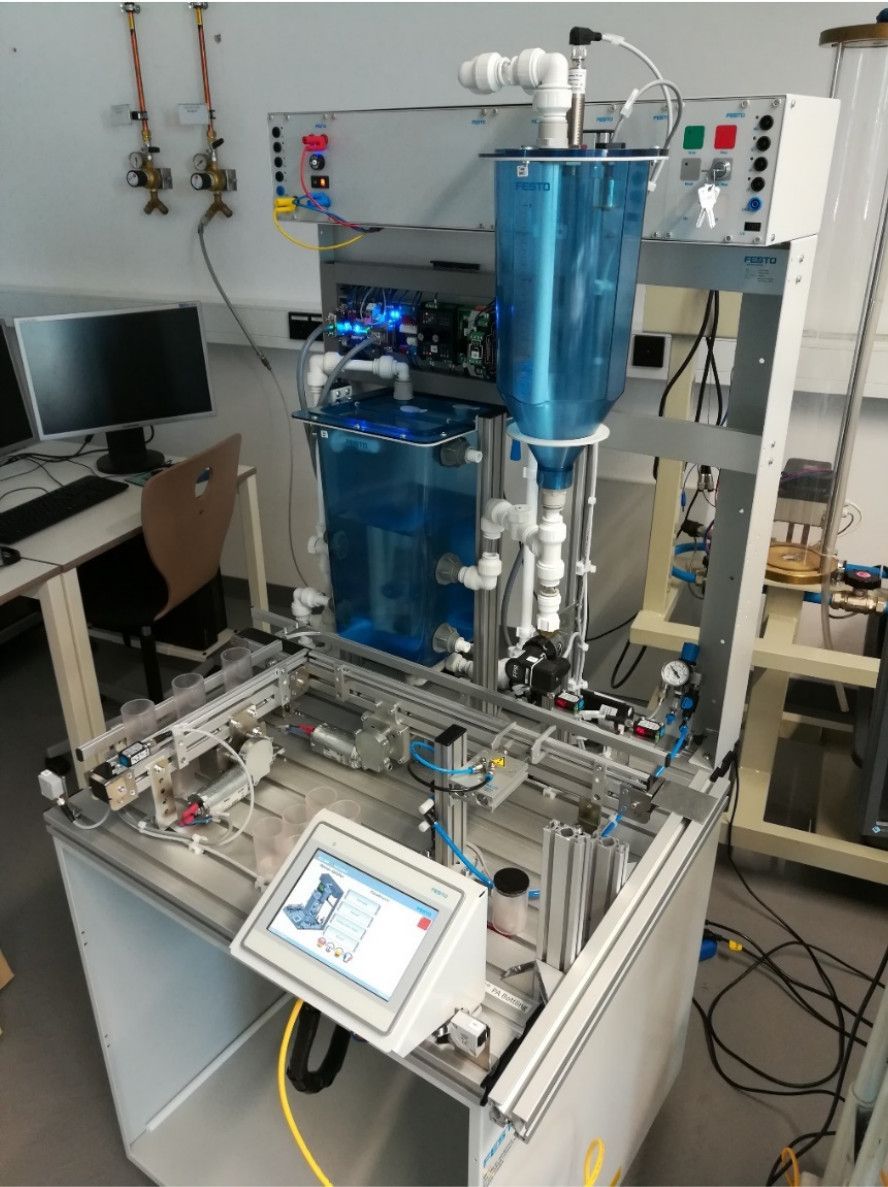

Expansion of remote service station and development of digital twin

Hardware extension

Up until now, students have had to operate the system, for example, to remove the cups filled with water and empty them back into the storage tank. Empty cups also need to be placed at the start of the conveyor belt.

For remote operation, the system would need to be extended to work fully automatically and continuously without the need for pupil intervention. This would require the cups to be automatically emptied and placed at the start of the conveyor.

Software extension/network connection

Remote programming of the system is only possible via the computer connected to the PLC, as a special version of CoDeSys is installed on it. Therefore, a remote access must be set up to allow the students to access the programming system, develop their own programmes, transfer them to the PLC and monitor the execution of the programme. Meanwhile, a high quality webcam should be used to monitor the system and give the students visual feedback on the progress of the programme.

Digital Twin

A digital twin of the system will be made available to the students for simulation purposes. Suitable software will be used to simulate the behaviour of the system and its response to PLC signals.

Contact

TU Ilmenau

Fakultät IA, FG Automatisierungstechnik

Dipl.-Ing. Axel Fink